The foundation of our approach to business is our Quality System combined with our comprehensive Process Improvement program. Through this approach, we develop and maintain written processes and procedures for everything we do. These processes and procedures are continuously monitored, evaluated, and adjusted in order to improve service and provide cost savings. All employees are required to use existing processes and procedures to accomplish their work. Managers/Supervisors are held accountable for training employees in the use of our Process Improvement system and to instill individual responsibility for quality workmanship.

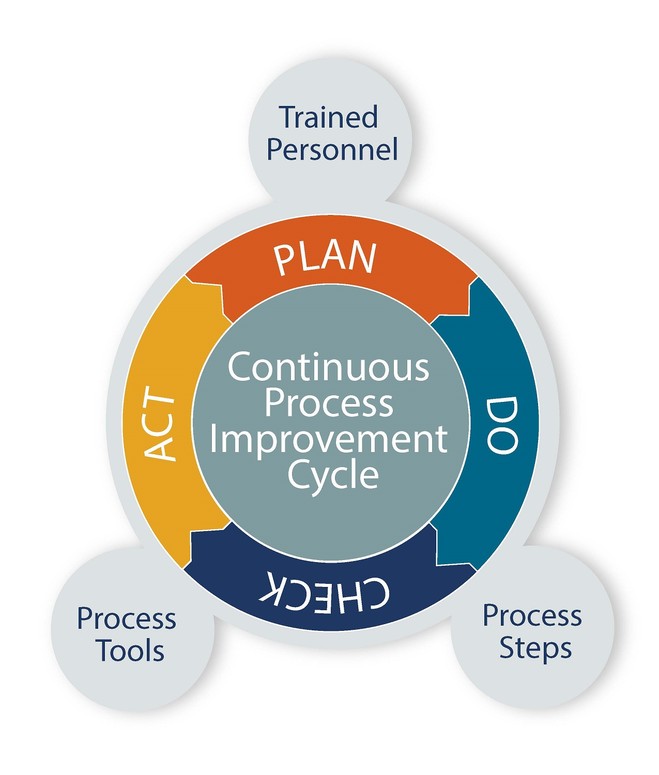

Though not yet ISO certified Integrity nonetheless strives to implement the tenets of the ANSI/ASQC Q9001-2000 Standard for Quality in our work to include a continuous improvement process (depicted below).

For existing processes the Continuous Process Improvement (CPI) cycle starts at the Act Phase. For new ones the Cycle starts at the Plan Phase. Each time a process goes through a CPI Cycle, each of the ten activities are performed. Cycle frequency is directly related to process improvement. One of the main elements of the CPI Cycle is the collection of quantitative measurement data and the evaluation of that data. Evaluated process measurement data is used to make adjustments to the process, tools and environment to improve the process. Without measurement data, a process cannot be evaluated or improved.

All supervisory personnel are or will be trained in the use of our Process Improvement Model and will be responsible for its implementation. To ensure implementation of the model, we perform internal reviews in all areas. These internal reviews identify any non-conformances and verify the existence and implementation of the Process Improvement Model.

Within each Seaport task order, an Internal Reviewer will be selected to perform the role of Program Advocate to help ensure the momentum and effectiveness of the quality and process improvement Program. He or she will institutionalize the Program within the Task and promote ownership of the quality and process improvement Program at all levels.

We have a Quality Council that consists of our senior management and the Process Improvement Team Administrator. The Quality Council’s charter is to define and continuously improve Integrity’s Quality System to ensure we deliver high quality products and services. The Quality Council is a management mechanism that ensures our Quality System is senior management driven.

The Quality Council is also responsible for the generation and maintenance of Integrity’s Quality System Manual which governs Integrity’s Quality System program and delineates Integrity’s quality policies and objectives.

We will document the processes used in producing Seaport deliverable products and services in manuals, procedures, checklist and flowcharts. Integrity “audits” these processes with a pool of internal auditors.